The Spectrum ULTRA Series thermal press is our new advanced compact bench top system with easy to use 4.3" COLOR touch screen controls (HMI). This more advanced model provides closed loop process controls and process parameter windows and also allows for additional options and accessories for better control and use while heatstaking.

Available in either 120V or 240V (50/60Hz) and with three different force models the Spectrum Ultra Series Heatstaking Press system is an ideal compact bench-top system for all thermal secondary and sealing operations. Press forces range from 0-1400 lbs depending on model chosen.

ULTRA Heat Staking Processes:

|

|

|

|

|

Insertion |

Staking |

Degating |

Date Coding |

|

Standard tips available for inserts up to 3/8" or M10 |

Custom platens available to stake several studs/tabs simultaneously. |

Heated sharp blades with beveled edge can cut gate flush to -.010 |

Use type holders or multi-wheel numbering for permanent part I.D. |

KEY Features:

- Multi bolt hole circle patterns in base for mounting lower jigs/fixtures.

- Rugged head assembly with non-rotation designs.

- Pre-drilled and Counterbored through holes for easy upper tool mounting.

- Micro-adjustable positive stop standard

- Pre-lubricated cylinder is suitable for oil free use.

- All presses are virtually maintenance-free as all moving parts are mounted in bushings and/or bearings.

- Two hand anti tie down safety circuitry on ALL bench-top models

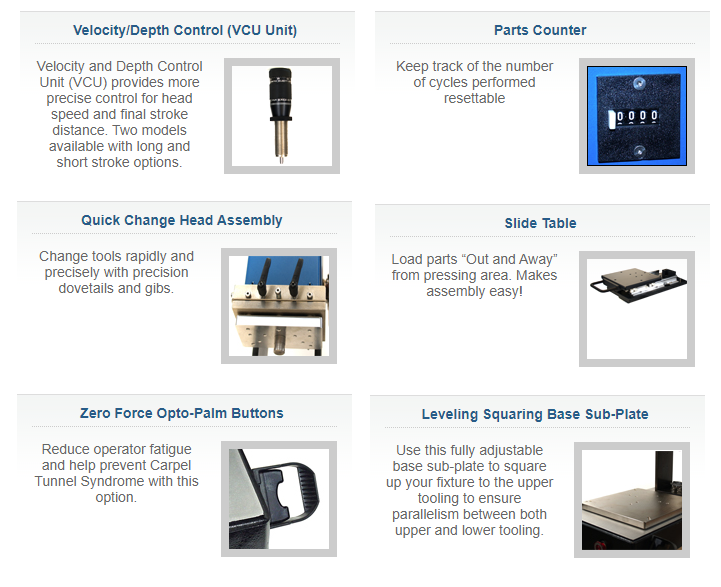

- Dual palm start buttons with optional Opto-Touch (Zero Force)

- Air Filter & Regulator with Tag out /Lock out.

- Adjustable nomenclature for optimizing process including gross head height, stroke in .001” increments, pressing forces, and stroke speeds.

- Easy change over to different tool and part heights via height adjustment crank with lock.

- Easy upper tool mount options including optional quick change precision dovetails with standard mounting plate.

- Parts counter option (resettable) available on all models

- Velocity and Distance Control using Sonitek’s NEW Proprietary optional VCU Device (Velocity & Distance Control Unit) Patent Pending.

- Optional base-mounted leveling plate for fixture squaring.

The ULTRA system offers these additional options and controls compared to the BASIC Series:

- Parts presence sensors

- Pre-Heat inserts option

- Strip Delay

- Pneumatic Clamping

- End of stroke/cycle complete sensor

- Low/high pressure alarms

- Out of temperature alarms

- Safety Light curtains

- Machine stands and guarding

- Rotary tables

- Customized systems

In addition the following options are also available in all models:

| Model | ULTRA S-3 | ULTRA S-5 | ULTRA S-10 |

| Power requirements: | 120 or 240V | 120 or 240V | 120 or 240V |

| Current draw: | Application Dependent | Application Dependent | Application Dependent |

| Pneumatic requirements: | Clean Dry Air @ 100 PSIG (690 kPa) Maximum | Clean Dry Air @ 100 PSIG (690 kPa) Maximum | Clean Dry Air @ 100 PSIG (690 kPa) Maximum |

| Maximum Force on part @ 100 PSIG | 325 lbs (147.4kg) | 510 lbs (231.3 kg) | 1400 lbs (635kg) |

| Air Consumption in CFM at 5 CPM: | .56 CFM at full stroke of 4.9” | .88 CFM at full stroke of 4.9” | 1.76 CFM at full stroke of 4.9” |

| Stroke Length | 4.9” (125mm) | 4.9” (125mm) | 4.9” (125mm) |

| Head Height Clearance | 0-13” (0-330mm) | 0-22” (0-559mm) | 0-22” (0-559mm) |

| Throat Depth | 4” (100mm) | 6” (152mm) | 6” (152mm) |

| Weight | 125 lbs (56kg) | 155 lbs (70 kg) | 210 lbs (95kg) |

| Ambient Operating Temperature | 41-122 F (5-50C) | 41-122 F (5-50C) | 41-122 F (5-50C) |

| Power Factor | 3.292 | 5.114 | 14.061 |

| CAD Drawings (.PDF) | S-3 ULTRA (.PDF)* | S-5 ULTRA (.PDF)* | S-10 ULTRA (.PDF)* |

| CAD Drawings (.STP) | S-3 ULTRA (.STP)* | S-5 ULTRA (.STP)* | S-10 ULTRA (.STP)* |

Electrical Load Limits: Download Load Limits.PDF*

*Specifications and design are subject to change without any notice or obligation on the part of the manufacturer.

Sonitek's NEW Spectrum Series Heatstaking Presses are cleverly designed to help you reduce the cost of both implementation and actual production in your assembly and pressing operations!

These small compact presses are ideal when precision matters for small heatstaking & sealing, forming, insertion, swaging, riveting membrane sealing or any other task that may require the use of compact precision assembly presses for your production floor! Since 1989, Sonitek has been producing high quality innovative and technologically advanced secondary assembly systems! Sonitek is the Market Leader for precise and innovative Heat Staking and Heat Sealing Systems & Tooling.

For more information about our Heatstaking Presses and the additional Sonitek products used in plastic assembly systems and joining operations please contact us today!