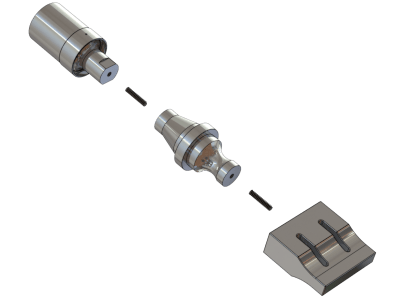

Regular maintenance of the ultrasonic horn stack (converter, booster, and horn) is crucial for ensuring consistent weld quality, efficient energy transfer, and prolonging the life of your equipment. This tutorial outlines the recommended procedures.

When to Perform Maintenance:

- Preventive Schedule: Start with a two-month schedule for new equipment. If no issues arise after a few cycles, extend this to every three months. Adjust based on equipment history and performance.

- Irregular Sounds: Perform maintenance immediately if you hear any unusual noises from the stack during operation.

- Decline in Weld Quality: If you observe uneven or incomplete welds, changes in weld appearance, uneven horn wear, sluggish actuator movement, or a perceived loss of power.

Required Tools & Materials:

- Spanner wrenches or bench vise (with soft jaws recommended for horns)

- Allen wrenches (for studs)

- Torque wrench

- Clean cloths or paper towels

- Cleaning solvent (check manufacturer recommendations)

- Fine-grit emery cloth or silicon carbide sandpaper (#280, #400, #600)

- Surface plate (granite recommended, a mirror can be an alternative)

- New Mylar washers (if applicable to your stack design)

- High-temperature molybdenum-based or high-pressure silicone-based grease (optional, check manufacturer specifications)

- Penetrant dye spray (optional, for crack detection)

Disassembly Procedure:

- Remove Stack: Carefully remove the entire stack assembly (converter, booster, horn) from the welder press/actuator.

- Separate Horn: Using appropriate spanner wrenches or a vise (protect the horn surface), carefully unscrew the horn from the booster.

- Remove Horn Stud: Use an Allen wrench to remove the stud connecting the horn and booster.

- Separate Booster: Using spanner wrenches or a vise, unscrew the booster from the converter.

- Remove Booster Stud: Use an Allen wrench to remove the stud connecting the booster and converter.

Inspection and Cleaning:

-

Studs:

- Clean studs thoroughly (brushing or ultrasonic cleaning).

- Inspect studs for any signs of wear, stress cracks, galling, or damage, especially at the threads and knurled ends. Replace if any damage is found. Note: Titanium studs often cannot be reused once torqued and should be replaced.

-

Mating Surfaces (Interfaces):

- Clean all mating surfaces (converter face, both ends of the booster, horn base) with a clean cloth and appropriate solvent. Remove any old grease, debris, or residue from previous washers.

- Inspect surfaces for:

- Fretting: Dark, dirt-like residue or corroded appearance.

- Wear: Circular wear patterns.

- Contamination: Hard deposits, rust, oil staining (yellow-brown indicates potential air supply contamination).

- Damage: Scratches, dents, or unevenness.

-

Washers (if applicable):

- Remove and discard old Mylar washers.

- Inspect washer seating areas for cleanliness and damage.

-

Components (Horn, Booster, Converter):

- Visually inspect the horn, booster, and converter bodies for cracks, especially in high-stress areas like horn slots or thin sections.

- (Optional) Use a penetrant dye spray system to check for microscopic cracks if suspected.

- Shake the converter gently; if it rattles, the internal crystals may be broken, requiring repair or replacement.

Surface Reconditioning (Lapping):

- Purpose: To restore flatness and remove minor fretting or contamination from mating surfaces. Do this only if necessary, as it removes material and can slightly alter component frequency.

-

Procedure:

- Secure a sheet of fine-grit emery cloth or sandpaper (#400 or #600 grit; use #280 only for significant damage) to a perfectly flat surface (granite surface plate preferred).

- Place the component's mating surface flat onto the sandpaper.

- Using light, even pressure (just the component's weight), stroke the component across the paper in one direction. Rotate the component (e.g., 120 degrees) and repeat. Use a crisscross pattern.

- Continue until the surface is clean and uniform. Remove minimal material.

- Clean thoroughly with solvent (ultrasonic cleaning is best) to remove all abrasive grit. Ensure threaded holes are clean.

- Check flatness (should be better than 0.025 mm / .001”).

Reassembly Procedure:

-

Stud Insertion:

- Ensure stud holes are clean and dry.

- Insert the correct stud into the booster and tighten it using an Allen wrench and vise/spanner wrench to the manufacturer's specified torque (often low, around 1.4 - 2 Nm / 12-18 in-lb, but verify). Do NOT overtighten studs into components.

- Repeat for the horn stud.

-

Surface Preparation (Optional):

- If recommended by the manufacturer, apply a very thin film of appropriate high-temperature/pressure grease to one of the mating surfaces (e.g., converter face or booster face). This fills microscopic gaps and aids energy transfer. Do NOT apply grease to threads.

-

Attach Booster to Converter:

- Ensure surfaces and threads are clean and dry.

- Place a new Mylar washer on the converter face (if applicable).

- Carefully screw the booster onto the converter stud finger-tight.

- Using a calibrated torque wrench and the correct spanner wrenches/vise, tighten the booster-converter connection to the precise torque specified by the manufacturer (this varies significantly by frequency and manufacturer, e.g., 185 in-lbs / ~21 Nm for some 30kHz Branson stacks, 420 in-lbs / ~47.5 Nm for some 20kHz Dukane stacks. Always refer to your specific equipment manual).

-

Attach Horn to Booster:

- Ensure surfaces and threads are clean and dry.

- Place a new Mylar washer on the booster face (if applicable).

- Carefully screw the horn onto the booster stud finger-tight.

- Using a calibrated torque wrench and the correct spanner wrenches/vise (use soft jaws for the horn), tighten the horn-booster connection to the exact torque specified by the manufacturer.

- Final Check: Ensure all components are securely tightened to the correct specifications.

Reinstallation and Testing:

- Carefully reinstall the assembled stack into the welder.

- Perform an ultrasonic test (often a button on the machine) to ensure the stack tunes correctly and the welder does not overload.

- Check the operating frequency (many modern welders display this) and compare it to the expected range. A significant frequency shift after maintenance might indicate an issue.

Important Considerations:

- Torque Values: Using the exact manufacturer-specified torque values for stack assembly is critical. Incorrect torque can lead to poor performance, overheating, and component failure.

- Cleanliness: Keep all components, threads, and mating surfaces meticulously clean throughout the process.

- Component Compatibility: Never mix components (studs, converters, boosters, horns) designed for different frequencies or from different manufacturers unless explicitly approved.

- Safety: Always disconnect power and air supply before performing maintenance. Use appropriate safety gear.

- Documentation: Refer to your specific ultrasonic welder's manual for detailed instructions, torque values, and recommended lubricants or procedures.

This comprehensive guide should help you maintain your ultrasonic welding horn stack effectively. Remember that proper, regular maintenance is key to reliable and efficient operation.