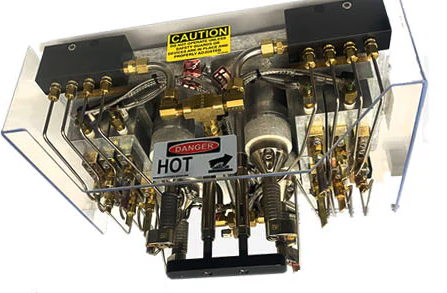

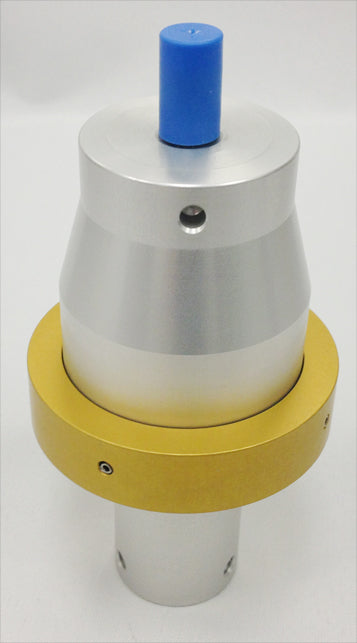

Custom Application Tooling

Sonitek is the industry leader in custom ultrasonic horns, heat staking, and air press tooling, with complete in-house engineering and manufacturing capabilities.

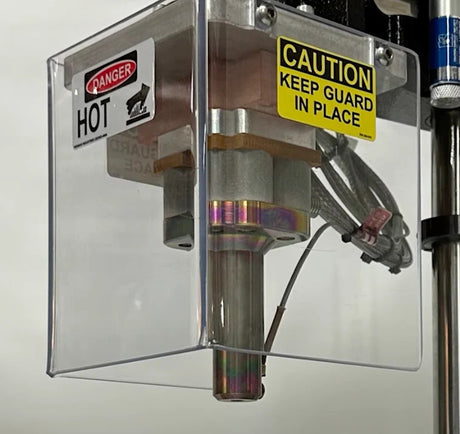

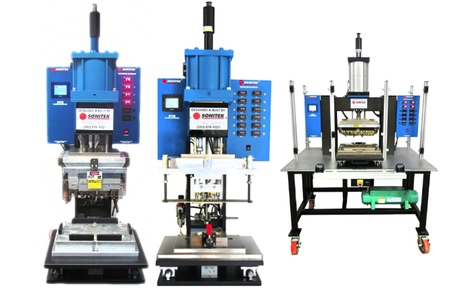

Heat Staking

Sonitek's heat staking presses provide high-speed, ergonomic, and repeatable solutions for precise thermal applications.

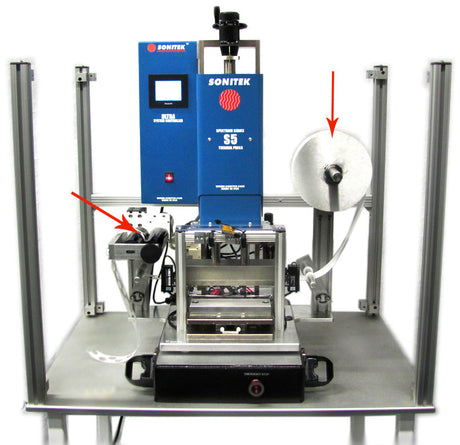

Ultrasonic Welding

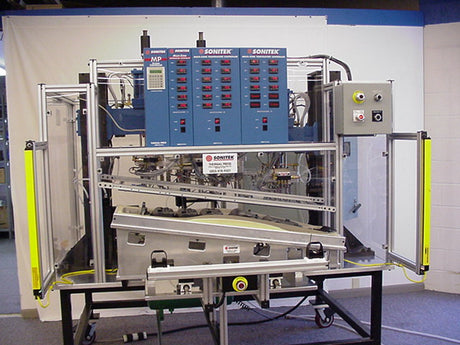

Our ultrasonic welders deliver precision, versatility, and advanced controls for reliable performance across applications.

Air Press

Our air presses deliver precise force for assembly, forming, stamping, and more, with options for automation.

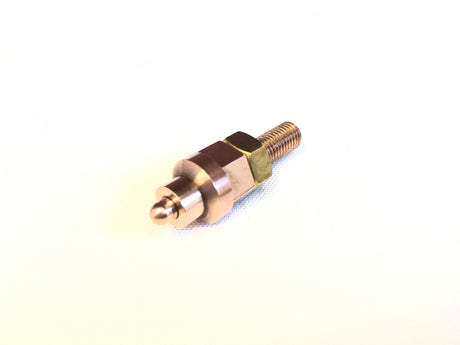

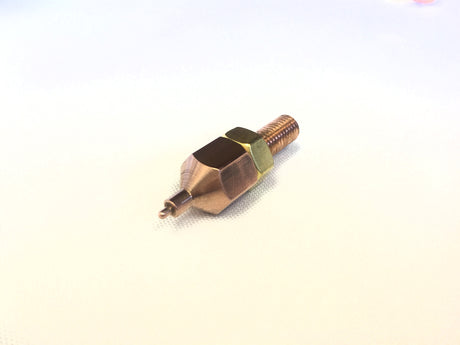

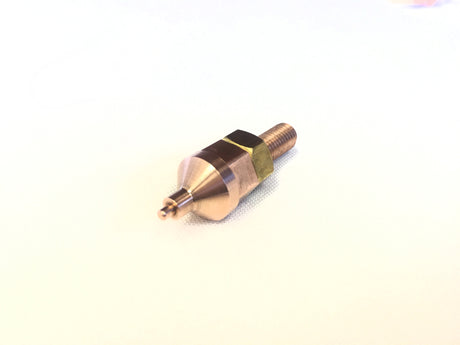

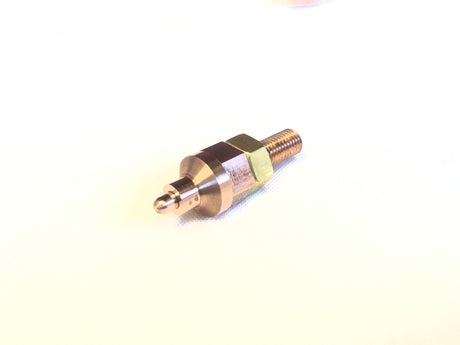

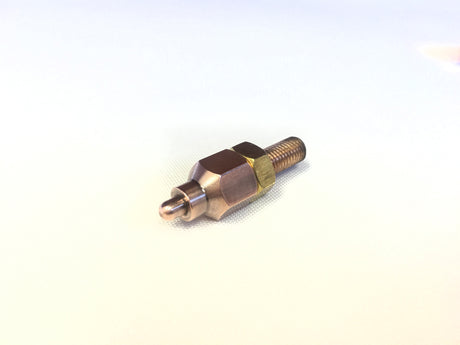

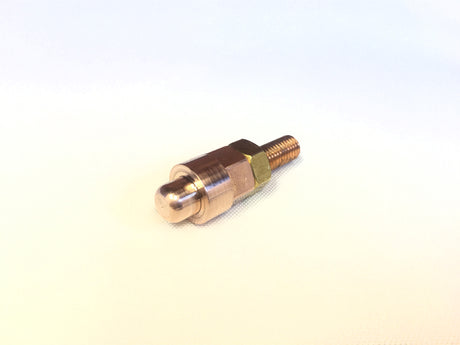

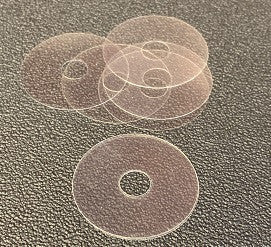

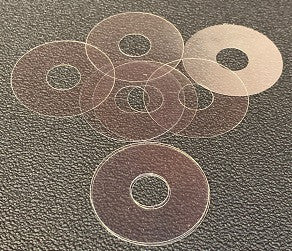

Parts Store

Sonitek offers in-stock spare parts with global shipping, available 24/7 for your convenience.

Our Process

Schedule a consultation-

Consult & Design

Analyze needs, collaborate on designs, and get tailored solutions for heat staking or ultrasonic welding.

-

Manufacturing & Quality Assurance

Start manufacturing with advanced tech and ensure quality through rigorous testing.

-

Delivery & Setup

Deliver custom machines with quality checks and provide setup with comprehensive training.

Resource Center

Visit Resource Center-

Design Guides

Design thermoplastic parts with our Heat Staking & Ultrasonic Welding Guide.

-

-

Application Engineering

We optimize tooling for ultrasonic welding, heat staking, and air press, enhancing performance.

-

Literature & Specs

Access our technical documentation, including Literature, Specifications, and Manuals.

-

Application Showcase

Discover plastic joining examples with detailed images and innovative design solutions.

-

Sell Your Equipment!

Sell your used heat staking or ultrasonic equipment to Sonitek for great prices and ease.