VERTEX mini/MAX Series

Available in 2 sizes and 4 forces.

VERTEX Series Heat Staking Machines

VERTEX MINI & VERTEX MAX side by side.

Key Features

- ✓ Self-Calibration Procedure, an industry first, for increased accuracy & compliance

- ✓ Extra-large Blanchard ground cast aluminum working platform with bolt hole circle patterns for mounting lower jigs and fixtures

- ✓ Precise dovetail actuator support with new rigid column design for accurate and repeatable gross head adjustment, equipped with position indicator and hand crank for easy adjustment

- ✓ 4-Post design precision guided non-rotating thruster/actuator with eight precision bearings and four ground and plated shafts for precise and repeatable process

- ✓ Available in two press sizes: VERTEX & VERTEX MAX. Comparison image (.JPG) & Comparison Dims. (.PDF)

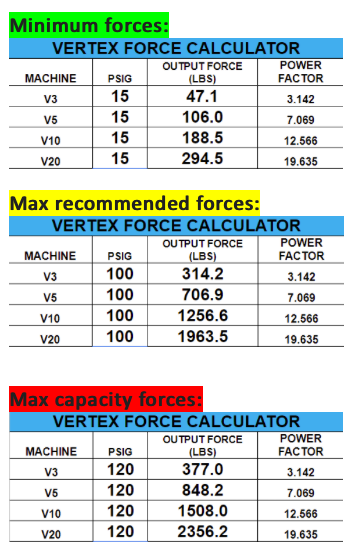

- ✓ Available in 4 thruster/actuator sizes (force values are at @ 100 psi):

- Vertex MINI Press:

- V3 model = 300 lbs.

- V5 Model = 700 lbs.

- Vertex MAX Press:

- V10 Model = 1250 lbs.

- V20 Model = 1960 lbs.

- Vertex MINI Press:

- ✓ 5" (127mm) stroke with adjustable micro-positive stop with .001" increments

- ✓ Thermal Runaway alarms with automatic heater shut off

- ✓ Heater shut down with any loss of line pressure or E-stop function

- ✓ Head Speed Controls for pneumatic portion of head travel for UP and DOWN speed control

- ✓ Velocity and Distance Control unit model VCU for dual stage speed control and precision adjustment of stake depth. (VCU instruction video)

- ✓ JOG MODE! New Feature: jog head up and down for setups

- ✓ Line pressure regulator (FR) with digital gauge read out and filter with dump valve and lock-out/tag out

- ✓ Rigid tool mounting plate for mounting upper heated tooling

- ✓ Vertex Digital micro controller system with 5" (MINI press) or 7" (MAX press) COLOR touch screen HMI that controls ALL Process Parameters including timers, temperatures and multilevel alarms

- ✓ HMI Integrated auto-tuning temperature controls

- ✓ Dynamic zone and heater output assignments via HMI allows for easy configuration of multi-zone tooling change-overs

- ✓ Secondary Temperature monitoring of tooling mode (view without control)

- ✓ JOB PRESETS - Multi Preset storage to store, recall, and assign parameters

- ✓ Resettable & Lifetime cycle part counters

- ✓ Hybrid Automation capable with I/O output and control options and accessories panel for rotary tables and integration of automation components and peripheral devices

- ✓ Multi-level Password Protection to prevent unauthorized access to controls

- ✓ Sonitek 4 zone (upgradeable to 8 or more on MAX press) temperature controlling power supply Model SW-1 equipped with settable auto-tuning PID controllers in F or C settings with digital LCD displays and with quick-connect heater/thermocouple connections located in rear

- ✓ THREE Year Limited Warranty

Heat Staking Processes

Insertion

Standard tips available for inserts up to 3/8" or M10

Staking

Custom platens available to stake several studs/tabs simultaneously.

Degating

Heated sharp blades with beveled edge can cut gate flush to -.010

Date Coding

Use type holders or multi-wheel numbering for permanent part I.D.

Rotary Tables & Safety Cell Machine Stands

Rotary Indexing Tables

Sonitek's Rotary Tables enhance productivity and streamline your production process. These precision-engineered tables offer smooth, efficient rotational movement for quick and easy part handling.

- Various sizes available

- Precision indexing for accurate positioning

- Durable construction for long-term reliability

- Easy integration with VERTEX series machines

Safety Cells / Machine Stands

Sonitek Machine Stands provide a stable and ergonomic foundation for your VERTEX series heat staking machines, designed for industrial environments and optimal operator comfort.

- Light curtains for safe operation

- Heavy-duty construction for stability and durability

- Casters for mobility (lockable for safety)

- Compatible with all VERTEX series models

- Fork lift tubes

- Available with storage options for tools and accessories

Options & Accessories

Calibration

Self-Calibration procedure & software for measurement values of Time, Pressure, Temperature, Distance for increased accuracy and compliance purposes. Sonitek supplies the following:

- User-Calibration Feature & Certificate:

- Enables embedded controls on Vertex machine for calibration.

- Includes initial Factory Calibration & Calibration Certificate

- Calibration Toolkit (P/N 600-1320):

- Includes 1 manual & Calibration Worksheet for step-by-step customer-calibration instructions for customer use.

- Includes 1 set of adaptor cables, fittings, & harnesses for connecting customer calibration equipment to a Vertex Machine

- Calibration Equipment (P/N 600-1321):

- Includes recommended calibration equipment such as a thermocouple simulator, digital pressure gauge, oscilloscope, blank Calibration Certificate, and Calibration labels.

Option 1 is sold per machine.

Options 2 and 3 can be used on multiple machines.

Specifications

| Model | VERTEX MINI Press | VERTEX MAX Press |

|---|---|---|

| Weight: | Approx. 170 lbs. (77 kg) | Approx. 300 lbs. (136 kg) |

| Footprint: | 14.01" wide (356mm) x 20.51" deep (521mm) x 33" high (838 mm) | 16" wide (406 mm) x 26.625" (676 mm) deep x 40.5" high (1029 mm) |

| Throat Depth: | 5" (127 mm) | 8" (203 mm) |

| Stroke: | 5" (127 mm) | 5" (127 mm) |

| Height Adjustment: | 13.5" (342 mm) | 19" (483 mm) |

Power & Zone Options

Air Requirement

ALL MODELS: Clean (5 micron), dry air, 80 psi @ 20 CFM min.

Air Consumption Calculation

Air consumption = Stroke length (in.) x Cycles/min x SCFM factor

Power Factor:

- 3.14 = V3 Series

- 7.07 = V5 Series

- 12.57 = V10 Series

- 19.64 = V20 Series

* Lower forces also available via an optional "Low Force Option" package.

Downloads

- Full Dimensions: Vertex MINI Press (.PDF) & Vertex MAX Press (.PDF). Also: Comparison Dimensions (.PDF)

- Literature: Download Literature (.PDF)

- CAD Files: Vertex MINI Press CAD (.STP) and Vertex MAX Press CAD(.STP)

- Electrical Load Limits: Download Load Limits.PDF

*Specifications and design are subject to change without any notice or obligation on the part of the manufacturer.